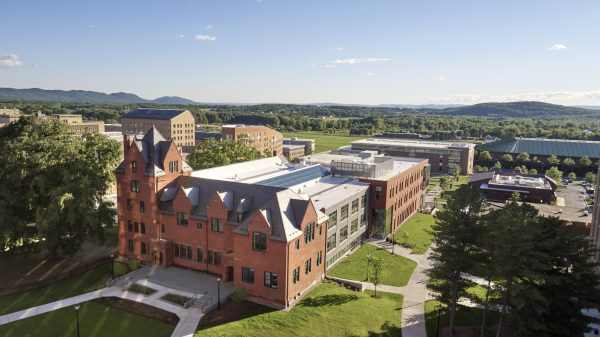

Transforming Industrial Legacy: Revitalizing Steel Plant Studios into Cutting-Edge Fine Arts and Fashion Hub

DOC served as construction manager for the expansion and renovation of the Steel Plant Studios, a former industrial building with brick masonry walls, concrete floors and exposed 15-foot ceilings. Prior to the project, the building housed Marist’s Art Gallery and a number of art studios. The project included new construction of a 34,000-square-foot addition and renovation of 13,500 square feet of existing space to house the Fine Arts and Fashion programs, including digital labs, maker space, studios and faculty offices.

Renovation work included selective demolition and structural work in the existing space along with interior and exterior masonry restoration. All windows were replaced with Hopes steel windows. All sills were replaced with precast. Adding to the complexity, the existing space was comprised of several different additions utilizing different materials such as brick and CMU for wall and various framing types.

Given its original use as a steel plant, it appears that as the plant grew, whatever steel was being produced at the time was used for construction of the joist system. Temporary shoring was installed for the removal of bearing walls and addition of steel support. Existing walls and joists were reinforced. Some were beyond repair and were removed and reconstructed. The roof support system was comprised of a mix of wood and steel. The roof was removed and replaced as part of the project.

Project Highlights

- Project site was located in an active part of campus, in close proximity to the main campus walkway, student residences, and parking areas. All phasing and sequencing of the work was coordinated with Marist College’s Facilities Department to ensure daily campus activities were not impacted.

Services

Project Contact

-

Jeremy Smith

Project Executive - Contact Jeremy Smith