Dynamic Arts Renovation Project Transforms Theater Hub, Enriching Performances, Connectivity, and Community in Vibrant Urban Landscape

Located in a densely populated urban residential neighborhood, this project was the renovation of the mainstage theater with a 490-seat audience chamber, stage improvements, scene shop improvements, additional space for rehearsals, a lobby/student lounge, art gallery space, and a 35-person conference room.

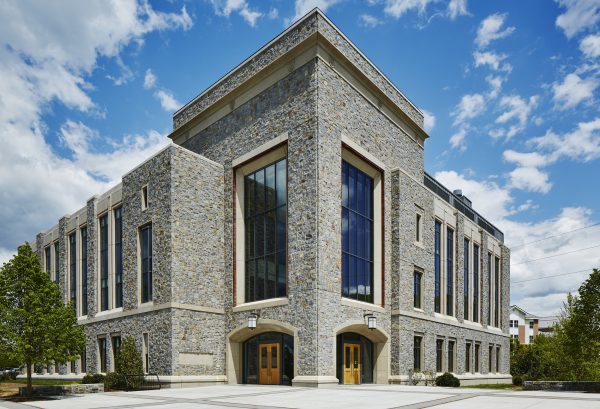

The mainstage theater is part of the Administration Building; a three-story brick veneer building that was built in 1958 on the university’s North Campus. The scope also included improvements to the existing building shell, sitework, landscaping and new MEP/FP Systems throughout the mainstage theater portion of the existing building.

The basement of the theater housed the main telecomm hub that served the entire campus and needed to be kept operational during the demolition and rehabilitation of the theater. DOC installed HEPA filters to maintain positive air pressure in the space and a temporary roofing membrane on the concrete floor above the room, to protect it from rain and water infiltration as the roof above was to be removed so that two 20,000-pound steel beams could be loaded into the building.

In addition to the telecomm hub, the campus steam line also passed through the basement. This was maintained throughout the construction phase and also required close coordination with all the subcontractors working in and around the lines.

Project Highlights

- Renovations took place while the building and surrounding campus remained occupied and operational

- New MEP/FP systems were installed throughout the mainstage theater portion of the existing building

Services

Project Contact

-

Thomas Walsh

Director of Business Development - Contact Thomas Walsh