Transforming a Historic Site into a Cultural Landmark

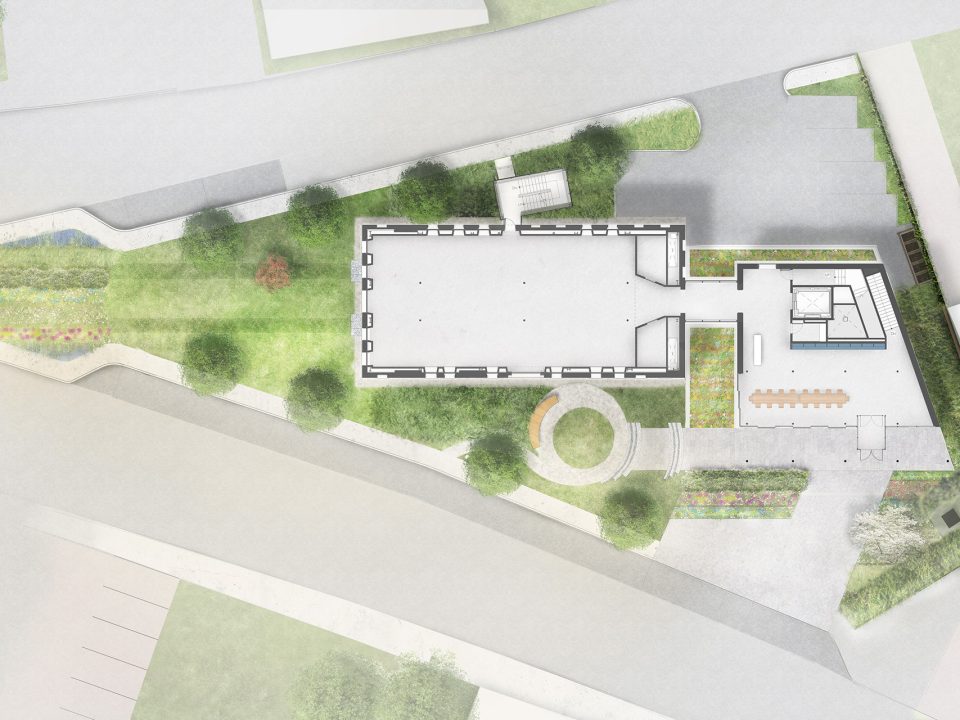

DOC is providing preconstruction and construction services for the new Shaker Museum in Chatham, NY. The project preserves Shaker heritage by retaining and fully renovating an existing 100-year-old, 15,150-sf unreinforced masonry building. The design inserts a new structural system within the historic envelope to meet current code requirements and create a collections storage area and three levels of exhibition space.

A new 11,950-sf addition connects to the renovated structure, complementing the historic building while introducing a distinct contemporary architectural element. This addition forms the museum’s main entrance and offers an open, welcoming space that immerses visitors in Shaker culture. Its cellar level houses public restrooms, additional collections storage, a learning center, and major MEP systems.

The structural design incorporates a cast-in-place concrete first floor, with Levels 2 and 3 and the roof framed in structural steel and Cross-Laminated Timber (CLT) plates. The project is under construction.

- Open Communication & Coordination: DOC is collaborating closely with the architect, the MEP/FP engineer, and the structural engineer.

- Complex Site Logistics: Managing tight-site constraints in a busy town, including exposed MEP/FP, minimal ceilings with CLT panels, and ongoing envelope and humidification work throughout museum spaces.

- Preconstruction Highlights: Providing preconstruction services, including SD/DD estimates, constructability review, schedule/logistics input, and a value management log.

Services

Project Contact

-

Jeremy Smith

Project Executive - Contact Jeremy Smith